Could wool change aviation interiors? Designing cabin interiors using wool as the core material could unlock benefits for both passengers and airlines from comfort to warmth without adding weight.

Transforming Aircraft Seating

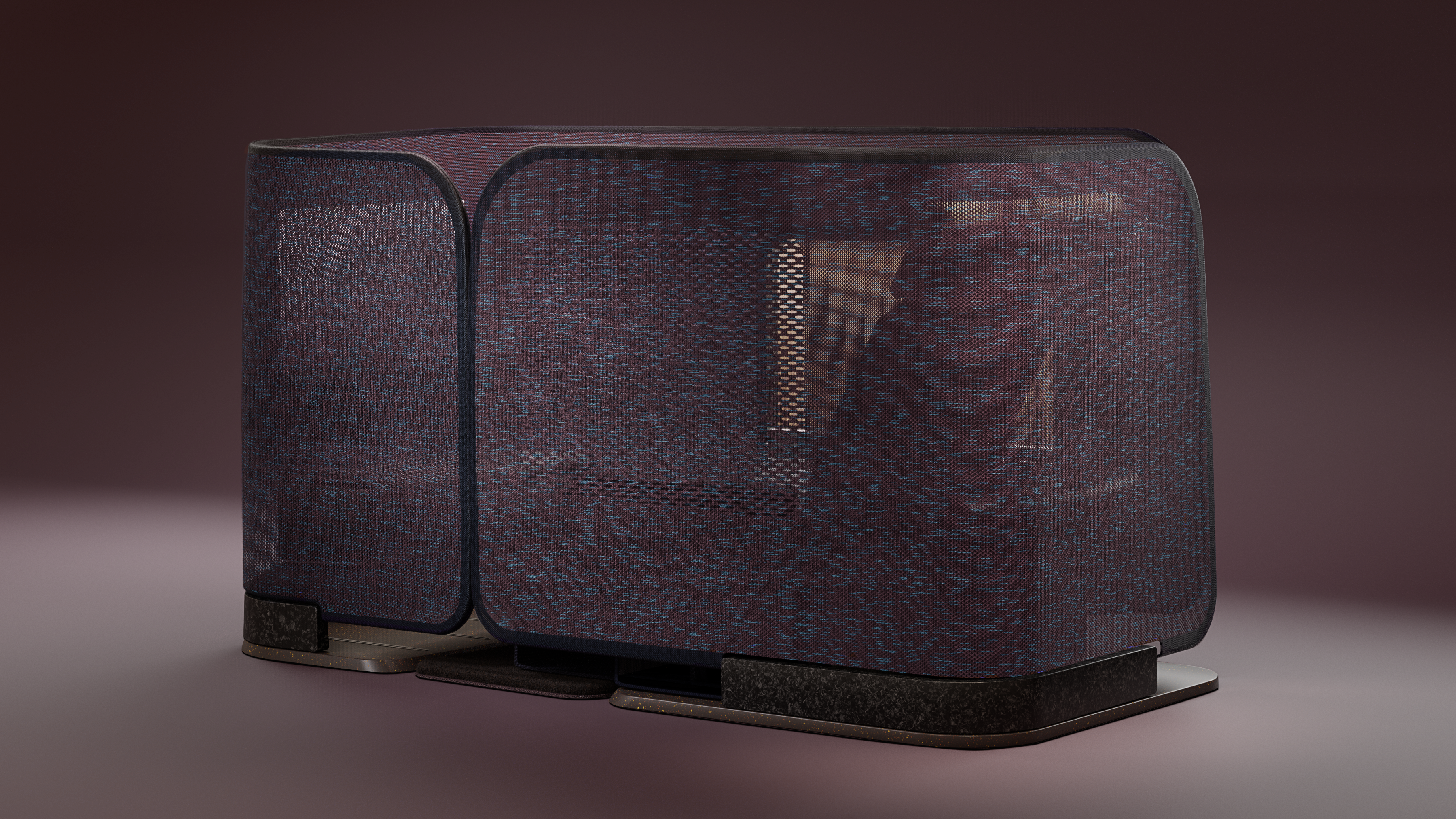

A forward-thinking collaboration from Caon Design Office and The Woolmark Company, Modulo is a revolutionary aircraft seating design concept that reimagines the future of premium cabin travel.

Modulo’s 3D knitted wool blend membrane transforms aircraft seating to address key issues such as weight reduction and the need for frequent cabin refreshes. With the wool fibre’s natural benefits including warmth and comfort without weight, Modulo is the next step in air travel comfort to challenge the status quo of flight travel.

Modulo is not merely a design study; it represents a leap forward in aircraft interior design, focusing on passenger experience, environmental impact, and operational efficiency. With Modulo, airlines have the opportunity to offer a refreshed, sustainable, and uniquely human travel experience, even on the most extended journeys.

“In exploring how to expand the capability of the wool fiber within the airline industry we address a major bugbear of airlines in that they have to spend huge sums of money and time in changing the feel of their cabin interiors. Passengers benefit too by having more of this wonderful material which breathes and allows us to play with light and opacity to create new scenarios for privacy and relaxation.”

HOW IT WORKS

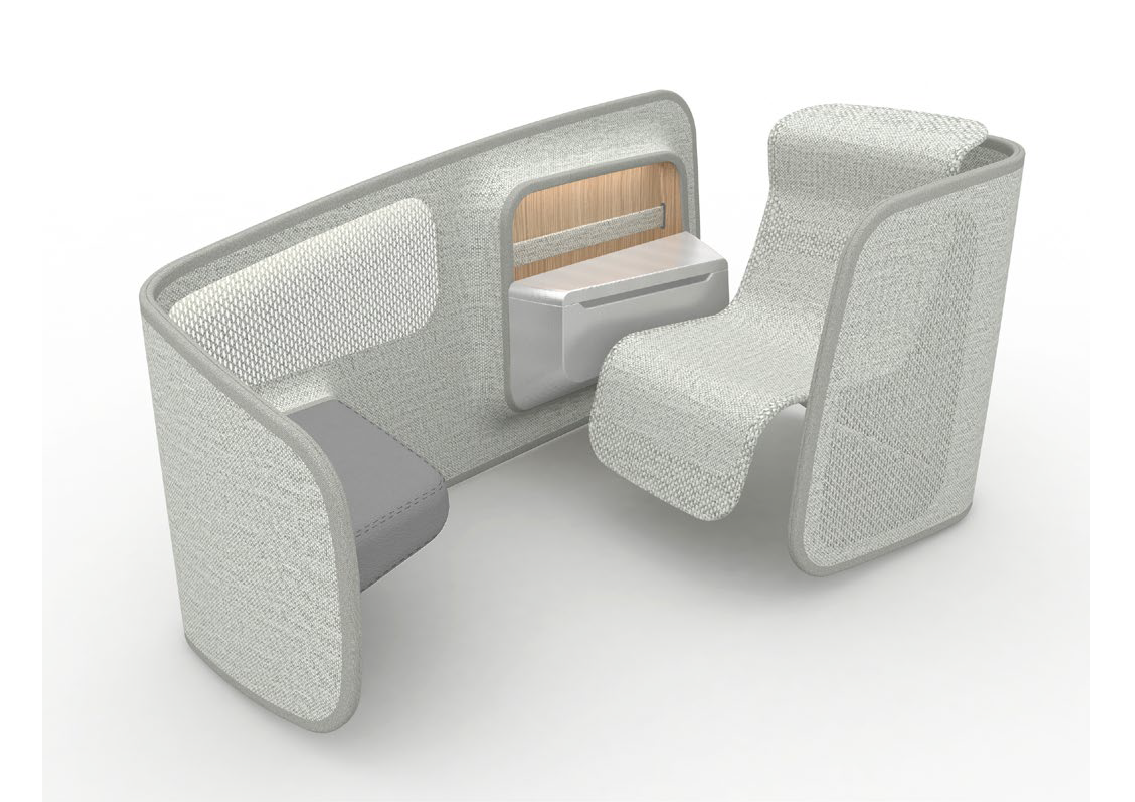

With modularity at the heart of its construction, Modulo is made from a lightweight yet robust framework of titanium, aluminium and carbon fibre. Modulo’s foundational structure underpins its distinctive fabric membrane with semi-transparent skin, shaped by advanced 3D knitting techniques to form a wool blend that is structural yet pliable.

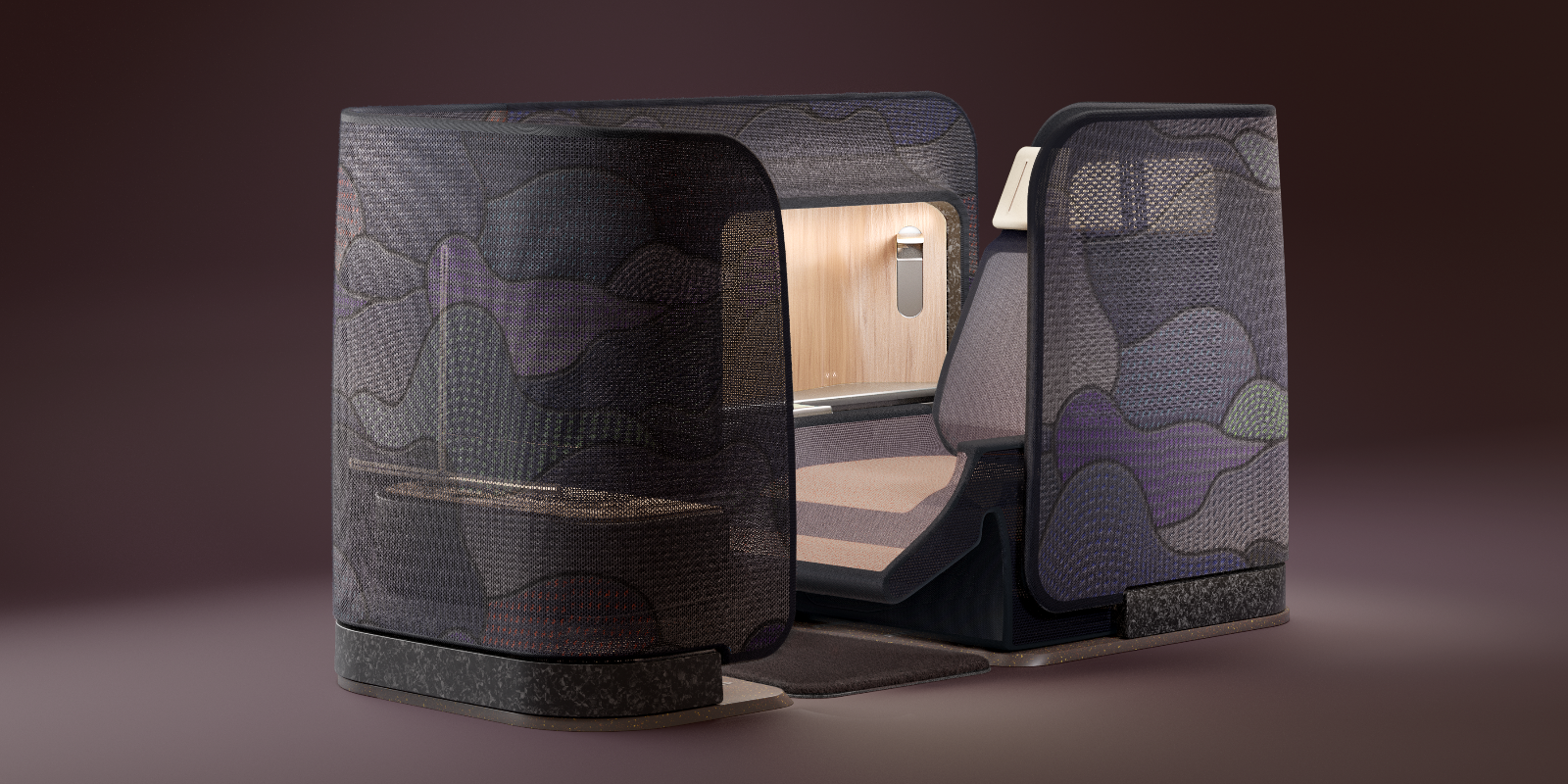

Carbon and elastic polymers integrated into the fabric give dynamic flexibility to allow the seat to smoothly transition from an open space to a private enclosure.

This visionary design extends beyond aviation, offering a versatile seating solution adaptable to future modes of transportation. Its lightweight structure and modular nature are ideal for the evolving landscapes of mass transport, hyperloops, autonomous vehicles, and electric aircraft.

Integrated Technology

Modulo's design is smartly integrated with sensors and technology to elevate the comfort and safety of passengers.

These sensors actively monitor and regulate seat temperature for optimal comfort.

Sensors also prompt passengers to move periodically, a feature designed to mitigate the health risks associated with prolonged immobility, such as deep vein thrombosis (DVT).

Click the dots to discover how this concept intends to integrate lighting, shelving and temperature control into the wool structure.

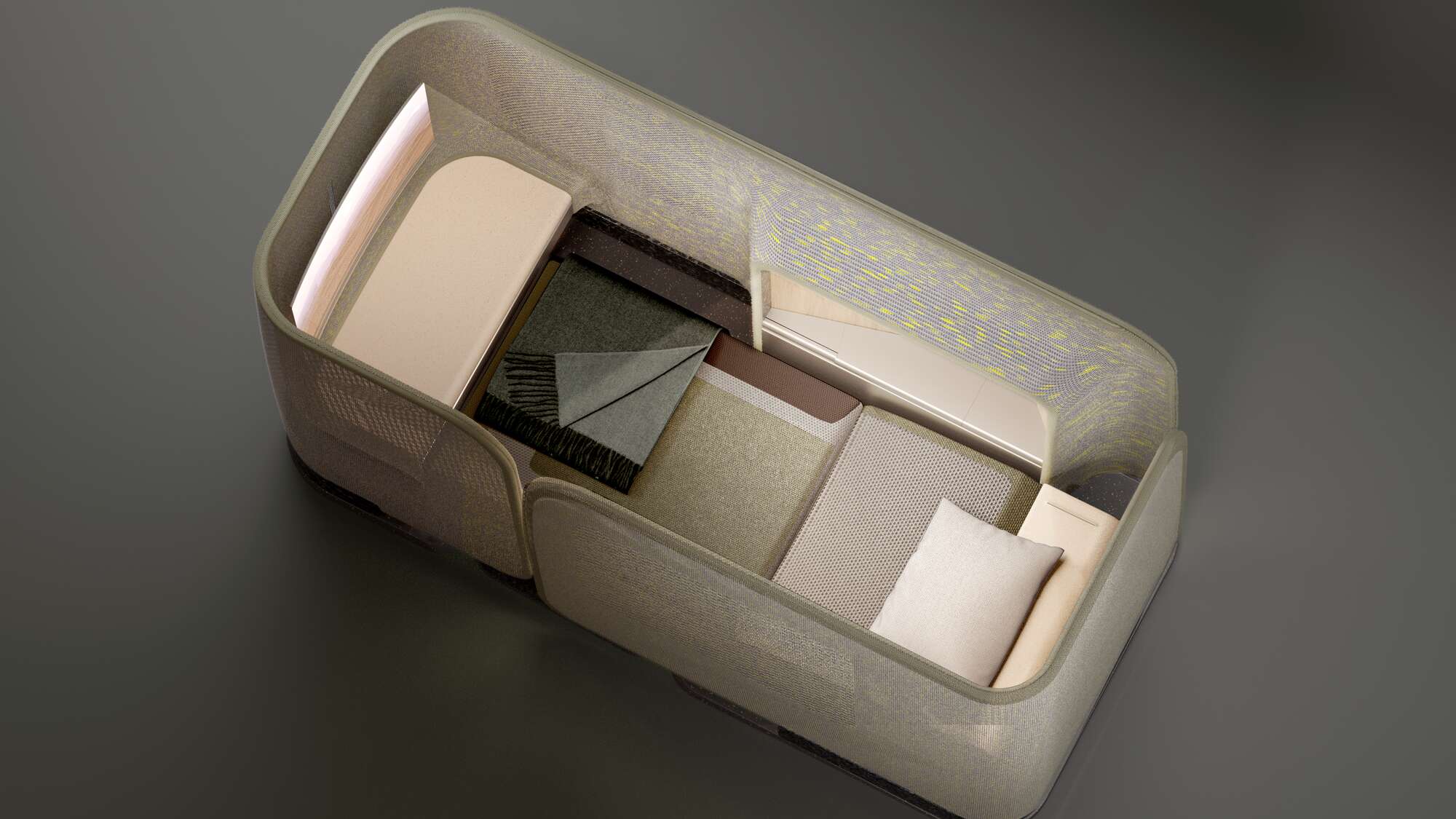

The translating structure of the seat allows us to experiment with opacity depending on the level of stretch. The wing depolys forward in private mode, obscuring the passenger but not blocking light.

The structure is held together by an underlying lightweight aluminium frame, onto which the wool ‘sock’ or knit is easily attached using a simple zipping or clipping mechanism.

The seat surface itself has integrated wadding for comfort and translates horizontally, allowing the passenger the ability to lay fully flat. The membrane design affords ergonomic benefits.

The predominant use of wool throughout the design gives the added benefits of a material that is hypoallergenic, breathable, flexible, anti-bacterial and sustainable, to name a few.

Potential integration of conductive fibers in the wool allows for further control over the inflight experience, giving passengers the ability to control the temprature of their seats.

Lights can be fitted to the underlying subframe to futher embellish the mood of the environment.

Use of wool in literature pockets as a soft and elastic band to hold the passenger’s belongings in place.

The padded leather footrest is a removable component which clips on and off during refurb.

The brushed titanium console houses the deployable meal table and has other stowage possibilities.